The company integrates production, research and development, and sales

Industrial Cooling System Cooler S&A CW3000, CW5000, CW5200, CW6000 Water Chiller for 60W-150W CO2 Laser Engraving Cutting Machine

A chiller is a mechanical device used to cool water and other fluids by removing heat through the process of refrigeration. Chilled water is commonly used in various industrial processes, air conditioning systems and equipment cooling applications. Chiller has different types, such as air-cooled chillers and water-cooled chillers, each offering specific advantages depending on the application requirements.

Product Features

Powerful Cooling:

S&A CW3000, CW5000, CW5200, CW6000 industrial Chiller uses standard R410a refrigerant to keep laser cutting and engraving machines up to 150W nice and cool during usage. Its 2.6 GPM flow rate and 0.9hp compressor can cool up to 5186 BTU per hour.

Capacious Tank:

The 1.6-gallon (6L) Industrial Water Chiller water tank is enclosed to reduce evaporation and provide long-term service between refills. The clear observation window lets you know when it's time to top off.

High-grade Ports:

The Industrial Water Chiller's inlet and outlet ports are made of premium brass for long-term corrosion-free performance. The careful design prevents any issues with leaks when it is operating.

Safety Operation:

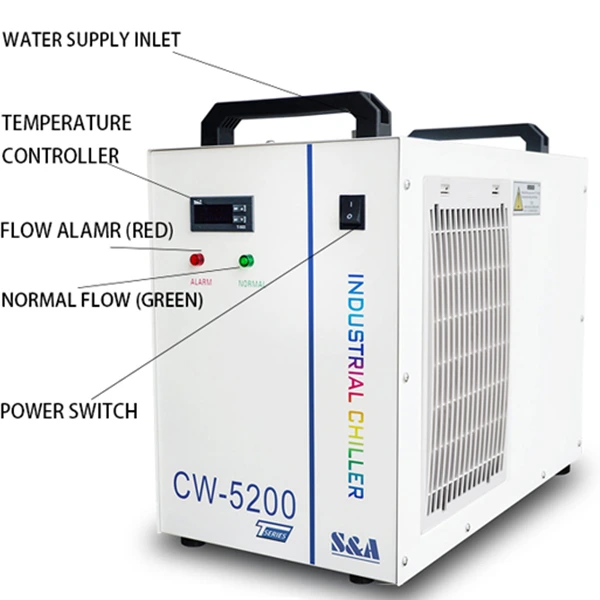

This Laser Tube Industrial Water Chiller includes internal sensors to keep temperatures within 0.3℃ of constant and to let you know via digital display, indicator lights and alarms when everything's going smoothly or when it's time to make adjustments.

Satisfaction Guaranteed:

S&A Industrial Water Chiller Strong warranty and friendly 24/7 customer service let you order with confidence that this CO2 Laser Chiller industrial will meet all your cooling needs for your CO2 laser Engraving Cutting machine.

Product Details

1. Independent production of sheet metal, High precision temperature control system, Temperature control accuracy can reach ±0.3℃.

2.It’s easy to move the chiller and check water filling. The water chiller can be moved easily from one place to the other by firm handle.

3. Inlet and outlet connector equipped

4. Multiple alarm protection

The laser machine will stop working once it receives alarm signal from the water chiller for protection purpose.

1. Famous brand cooling fan and level gauge

The high quality and low failure rate SAN JU cooling fan has been equipped inside.

Special Domain Chiller

Hanli Chiller

About Us

Accurate Laser Technology (Suzhou) Co., Ltd is a professional manufacturer of laser equipment such as laser welding, laser cleaning, laser marking and laser cutting equipment etc.

Laser equipment has been widely used to precision machining, sheet metal processing, smart home, automobile, shipbuilding, advertising and decoration, kitchen and bathroom appliances and other industries. Based on the business philosophy of high quality and low cost, Accurate Laser keeps innovating at equipment manufacturing and application technology. The commitment of Accurate Laser is to provide the customers with better products and services all over the world.

FAQ

Accurate Laser Technology (Suzhou) Co.,Ltd. is a manufacturer of laser equipment such as laser welding, laser cleaning, laser marking and laser cutting etc.